Dynamic Rocker Back Interface – Indicators that the elastomers need to be changed Part 2

Michelle L. Lange, OTR/L, ATP/SMS

Part 1 of this series addresses factors which contribute to elastomer wear. You can read it here.

The elastomers in a Dynamic Rocker Back interface (DRBi) are designed to absorb client forces, store force as energy, and use that energy to return the client to upright sitting. The elastomer absorbs forces that could otherwise lead to damage to the wheelchair frame, mounting hardware, and seating system. As such, the elastomer experiences wear and tear, rather than the rest of the equipment. Once showing signs of wear, the elastomer needs to be replaced in order for the DRBi to function properly.

So how do you know if the elastomer needs to be replaced?

1. The ‘Bulging Disc’

As the elastomer begins to wear, this material experiences deformation. This can make the elastomer appear to be ‘bulging’ within the DRBi hardware. The amount of elastomer that can be visualized may also decrease.

In this picture, the worn Green Impact (upper) elastomer is shown next to a new Blue Impact elastomer. Note the difference in height and width, as the Green Impact elastomer has been deformed by extreme and repeated client force. On the right side are a pair of Rebound (lower) elastomers which further assist in client return to upright and are also contained, though cannot be visualized, in the DRBi hardware. The worn Rebound elastomer to the left is now shorter and wider, as well. The Impact elastomer includes an impact cap which, in this case, was also cracked.

The end of the worn Green elastomer (top) vs. a new elastomer. This shows the deterioration and separation of the “skin” from the internal material.

On the right is the cracked impact cap.

The worn elastomer appears to bulge and less of the elastomer can be visualized.

The new elastomer shows no bulging and more of the elastomer can be visualized.

2. The Sagging Back

Another indicator that the elastomer is worn is a ‘sagging back.’ As the elastomer wears (deteriorates), the seat to back angle may actually increase (more open) as the space between the DRBi hardware decreases. A more open seat to back angle can lead to a change in the client’s position. It is best to replace worn elastomers before the back begins to sag, as a change in client position could impact function.

Alex’s back is sagging posteriorly, opening her seat to back angle to approximately 105 degrees due to a worn elastomer.

The seat to back angle is restored to 90 degrees with a new elastomer. Each individual’s optimal seat to back angle is determined during the evaluation.

3. Difficult Latching

As the elastomers wear and the back may begin to sag, the DRBi hardware will become more difficult to Latch or lock-out. This is an indicator that the elastomers need to be changed.

In this picture, Alex is sitting upright, but only because the DRBi is latched. As soon as it was unlatched, the back sagged posteriorly (see above). In order to latch the DRBi, her caregivers had to pull up and forward on the backcane push handles. Once a new elastomer was placed, the DRBi could be readily latched, and the back no longer sagged.

With a new elastomer in the unlatched position.

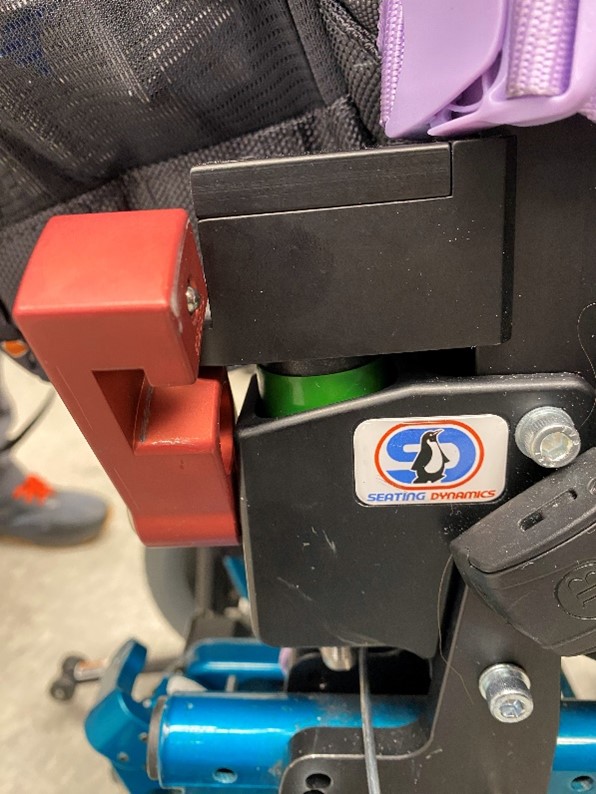

The red latching plate can readily be swung into position to latch the DRBi. Looking at top corner of the latch plate you see an area with the red plating worn off as a result of contact with the rear edge of the actuator arm, a result of worn out elastomers.

Alex

The young lady in each of these examples exhibits large, repetitive, and forceful movements. She can wear out her elastomers in as short a time as 3 months! When we saw Alex in a clinic in Denver with her OTR, Becky Breaux, Greg actually taught Alex’s Dad Luke how to change the elastomers. We also reviewed all the signs that he could look out for, indicating the elastomers needed to be replaced again. Now, instead of ordering a replacement elastomer kit which includes all resistance levels, the supplier can order the Impact elastomers with impact cap individually and specify the quantity desired, in her case Green elastomers – Extra Firm. The Rebound elastomers, always clear, may be ordered individually in quantity as well. The part numbers listed below are for a set (LH & RH sides of the chair). Specify the number of sets desired.

-

- 6191-101 Soft Impact, Yellow with Impact Cap.

- 6191-102 Medium Impact, Clear with Impact Cap, also use in Rebound position.

- 6191-103 Firm Impact, Blue with Impact Cap.

- 6191-104 X-Firm Impact, Green with Impact Cap.

If you are unsure what level of resistance is required, check out this post, this post and our Quick Class on this subject.

Summary

Optimally, the elastomers should be checked at least every 6 months or more frequently for clients with a history of large, repetitive, and forceful movements. Remember, wear and tear does not mean that the Dynamic Rocker Back interface isn’t doing its job. The elastomer is designed to absorb client forces that could otherwise lead to client injury and equipment damage. A worn elastomer has done its job well!