Dynamic Rocker Back interface – Factors which contribute to elastomer wear Part 1

Michelle L. Lange, OTR/L, ATP/SMS and Greg Peek, President

The elastomers in a Dynamic Rocker Back interface (DRBi) are designed to absorb client forces, store force as energy, and use that energy to return the client to upright sitting. The elastomer absorbs forces that could otherwise lead to damage to the wheelchair frame, mounting hardware, and seating system. As such, the elastomer experiences wear and tear, rather than the rest of the equipment. Once showing signs of wear, the elastomer needs to be replaced in order for the DRBi to function properly. This was addressed in a previous blog, however we love to share new information and perspectives!

How do the Elastomers in the Dynamic Rocker Back interface work?

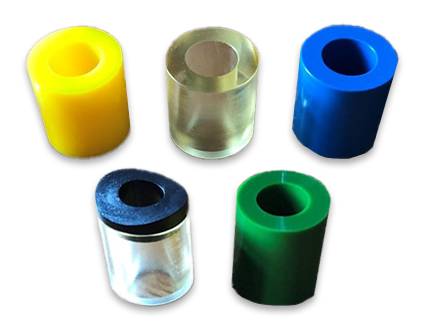

Let’s start with Seating Dynamics DRBi elastomer basics. The left and right hand DRBi assemblies are identical as far as components and function are concerned. Each DRBi has two elastomers, an upper Impact elastomer and a lower Rebound elastomer. The Impact elastomer is available in different resistance levels – Yellow (soft), Colorless/Clear (medium), Blue (firm), or Green (extra firm) and has a Black cap the top. The Rebound elastomer is always Colorless or Clear.

The Impact elastomer absorbs intermittent client forces. This elastomer can also respond to a constant load caused by one of these scenarios:

- The degree to which the seat to back angle is open will result in a degree of load to the elastomer, compressing it.

- Backpacks or anything else hanging on the back will increase elastomer load and compression.

Both of these scenarios will apply load and reduce the amount of compression available when an additional impact load is applied by client forces. As a result, the elastomer may wear sooner than if subjected to solely client forces.

Both of these scenarios will apply load and reduce the amount of compression available when an additional impact load is applied by client forces. As a result, the elastomer may wear sooner than if subjected to solely client forces.

Summary

Remember, wear and tear does not mean that the Dynamic Rocker Back interface isn’t doing its job. The elastomer is designed to absorb client forces that could otherwise lead to client injury and equipment damage. A worn elastomer has done its job well!

Keep an eye out for Part 2 of this Blog when we will address the top 3 ways to determine if the DRBi elastomers need to be replaced!