Will my client break the Dynamic Seating?

Updated 9/26/2022

Michelle L. Lange, OTR/L, ABDA, ATP/SMS

Dynamic Seating is often used to prevent equipment breakage, specifically of the wheelchair frame and seating system. The Dynamic components absorb strong, repeated, sudden, and/or sustained forces, hence protecting vulnerable areas of the seating and mobility base. This was addressed in two prior Blogs (Dynamic Seating to Prevent Equipment Breakage, part 1 and part 2). But what about the Dynamic Components themselves? Just how durable are these?

For the answer, I asked Greg Peek, the designer of the Seating Dynamics product line. According to Greg, the dynamic component needs to offer sufficient travel yet ensure that client movement never reaches the limit of that travel. At any point of mid-range travel, there is essentially no load applied to the wheelchair frame. The dynamic component is, in theory, receiving the load and containing it internally, rather than transferring it to the frame. If the dynamic component reached the end of its available travel, the forces would be transferred to the frame. Proper design prevents this from happening.

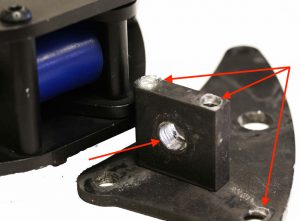

I next asked Greg why some Dynamic Seating products are prone to breakage. His response: “There are many factors that contribute to the reliability of a product. In my opinion, the two biggest factors are the design itself and the material it is made of. You must have a good understanding of what the end result must accomplish to design a product that performs up to expectations. Looking at Image 1 below, you see a competitor’s new Dynamic Back unit which uses many parts that are bolted together. Not counting any components or hardware used to attach this to the wheelchair, there are 7 major structural parts, most of them stamped from 3/16” thick aluminum plate (alloy unknown), 12 screws per side and 3 bolts with nuts for a total of 15 threaded fasteners per side of the chair. All but one of these goes from side to side (completely through the unit) and are subject to shear forces."

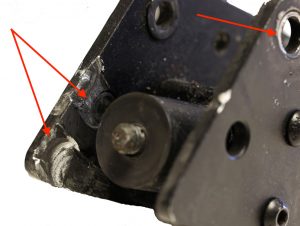

"A dynamic back component must move to provide dampening of the client energy transmitted into the wheelchair. Anything that moves will ultimately experience some amount of wear, somewhere. When movable parts wear, the necessary clearance between parts increases (a steel bolt through a softer aluminum part causes the hole in the aluminum to change size and shape, see Image 4 below), which may cause functional problems and will ultimately result in some form of product failure.”

How do the Seating Dynamics components avoid this problem?

“I am a design fanatic and invest significantly more time and money in a larger piece of raw material and machine time. The end result is one piece components with many integral features and functions designed into it, not bolted together. For example, the Dynamic Rocker Back Interface (DRBi) housing for a Quickie Iris starts as a 2.67 pound solid piece of custom extruded 6061-T6 aluminum bar stock. Ten minutes in one of our big CNC machining centers and that piece of aluminum loses almost 2 pounds."

"In comparison to the product photo shown in Image 1, we have only 6 machined parts and 1 bolt in the DRBi! Our finished DRBi assembly is 60% heavier, weighing in at 2.65 pounds per side versus 1.68 pounds for the product in Image 1. Ours is not the cheapest, lightest, or quickest solution however, with our clientele, cheap, light and quick is not likely to hold up for long.”

"Images 3, 4 and 5 below are components of a unit as shown in Image 1 which had been in use for six months. Notice the many elongated holes and worn and gouged areas, all a result of a design which is not robust enough to hold up to normal use of our clientele."

Wear & tear on competitor’s product after 6 months of use. (click to enlarge)

If I am looking for a new washing machine, I want to ensure that I can wash many, many loads of laundry before product failure – in my home, about 50,000! Of course, I want the washer to get my clothes clean, too. For the clients I work with, I want Dynamic Seating components that get the job done. But I’m also interested in the components getting the job done for a long time.

Great brief article

Thanks

Thanks Missy, we appreciate your comment!